Hammer Exhaust Fan Manufacturers and Exporters in India

As leading Hammer Exhaust Fan Manufacturers in India and Hammer Exhaust Fan Exporters in India, we handle every aspect of your bulk order with precision and care—from the moment our engineers arrive on-site to assess structural loads, heat-load requirements, and optimal louver placement, through detailed CAD designs that ensure your negative-pressure exhaust system meets BIS ISI, CEA, and, where needed, PESO/ATEX certifications. Our state-of-the-art Pune facility then fabricates each GI-body, stainless-steel-blade fan under rigorous ISO processes, after which our export team secures all necessary documentation, arranges compliant packaging, and coordinates logistics to guarantee damage-free, on-time delivery anywhere in India or beyond. Upon arrival, our certified technicians perform turnkey installation and commissioning—fine-tuning blade pitch, verifying airflow performance, and training your maintenance staff on preventive care. Backed by 24/7 technical support and customized service plans, we ensure your industrial hammer exhaust fans deliver maximum ROI, long-term durability, and regulatory peace of mind, reducing downtime and boosting workplace safety across every facility.

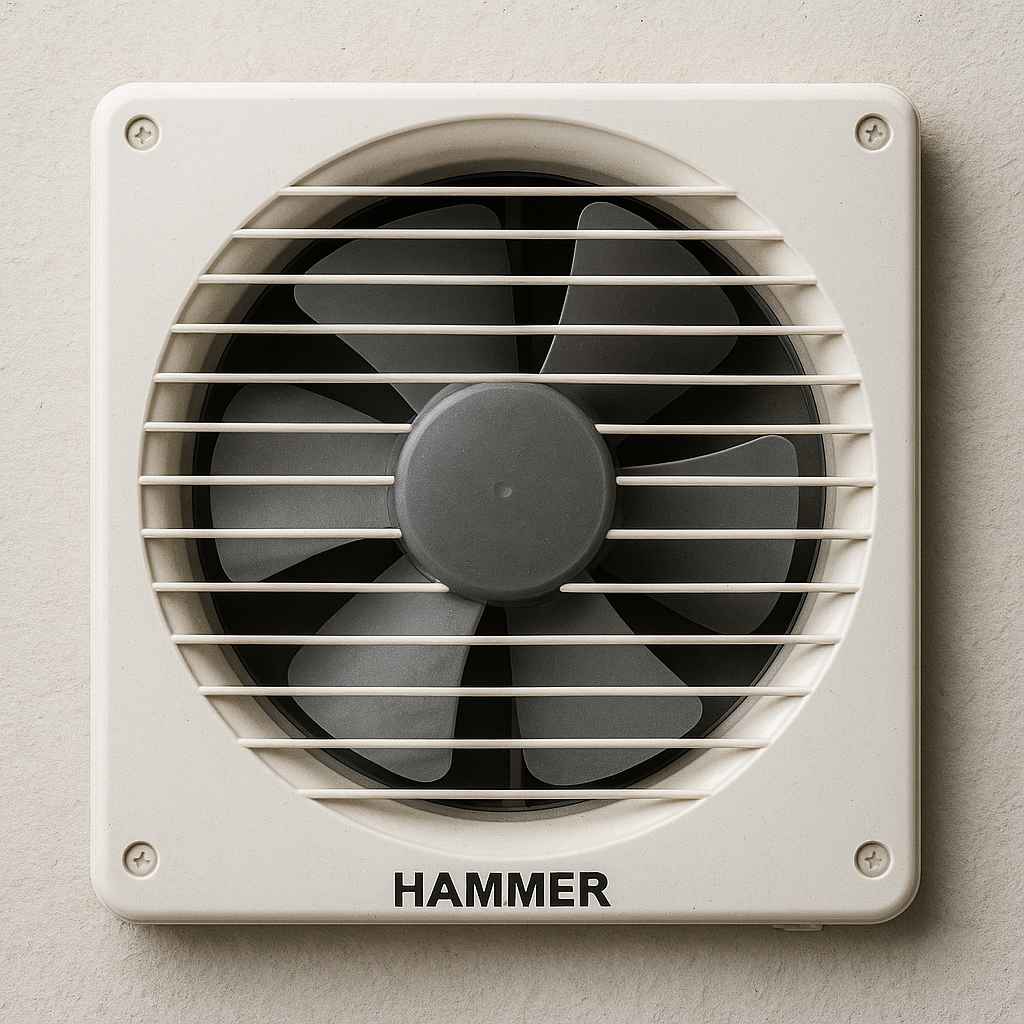

What is a Hammer Exhaust Fan?

A hammer exhaust fan, often called a negative pressure exhaust fan or push-pull fan, is designed to create controlled airflow by pulling hot, stale air out of large enclosures and drawing in fresh air through intake vents. Constructed with a robust GI body and stainless-steel blades, these fans resist corrosion and deliver high volumetric flow at low noise levels. Gravity-operated louvers on the fan’s intake side prevent dust, debris, and birds from entering the facility, ensuring uninterrupted, low-maintenance operation.

Technical Specifications

| Model |

Size (mm) |

Dia (inch) |

Air Vol. (m³/h) |

Noise (dB) |

Speed (RPM) |

Power (kW) |

Voltage |

| SSIAEIPL-1750 |

1750 × 1750 × 450 |

62″ |

68 000 |

70 dB |

400–450 |

1.8–4 |

380 V |

| SSIAEIPL-1530 |

1530 × 1530 × 400 |

52″ |

57 000 |

70 dB |

450 |

1.5–4 |

380 V |

| SSIAEIPL-200 |

200 × 200 × 170 |

6″ |

1 000 |

< 60 dB |

2 200 |

0.15–4 |

220 V |

| (Full range of 15 models from 200 mm to 1 750 mm available) |

Types of Hammer Exhaust Fan

- • Drop-Hammer Exhaust Fan: Featuring a medium sweep and compact housing, this model excels in general factory ventilation. Its gravity louvers provide reliable back-draft protection, minimizing dust ingress.

- • Industrial Heavy-Duty Exhaust Fan: Designed for high-capacity airflow, it uses reinforced GI construction and high-torque motors. Ideal for steel mills, foundries, and large warehouses requiring robust, continuous operation.

- • Poultry Exhaust Fan: Engineered for barns and hatcheries, this variant balances airflow and noise. Its stainless-steel blades resist ammonia-induced corrosion, ensuring long service life in humid, organic environments.

- • Push-Pull Fan Configuration: Combines paired inlet and outlet fans to establish negative pressure zones. This system efficiently evacuates hot air while drawing in fresh air, optimizing climate control in segmented facilities.

Applications of the Hammer Exhaust Fan

- • Manufacturing Halls: Rapidly removes heat and fumes from welding, forging, and machining areas.

- • Cold-Storage Loading Bays: Prevents condensation and frost buildup by exchanging stale air with ambient outside air.

- • Poultry Farms: Maintains optimal barn temperatures, reducing heat stress on livestock and improving air quality.

- • Automotive Paint Booths: Ensures consistent airflow for flawless finishes and compliance with VOC regulations.

How Hammer Exhaust Fan Works

Hammer exhaust fans operate on negative-pressure principles: the high-speed motor spins stainless-steel blades to draw warm, contaminated air through the inlet louvers. As the louvers close via gravity when the fan stops, they block reverse airflow and block dust and birds. The continuous extraction creates a slight vacuum inside the building, which pulls fresh air through strategically placed intake vents. This push-pull dynamic ensures efficient air exchange and even temperature distribution, all while minimizing energy use and noise.

Hammer Exhaust Fan Ordering, Compliance, and Safety Information

To place a bulk order, begin with a site survey - our engineers assess structural load capacity, heat-load calculations, and intake vent placement. Next, review our detailed quotation, which includes BIS ISI and CEA compliance certificates; for hazardous zones, we can add PESO/ATEX approvals. Upon purchase order confirmation, we schedule manufacturing and export documentation. After delivery, our certified technicians handle installation, commissioning, and operator training. We then provide preventive-maintenance plans and 24/7 support, ensuring your hammer exhaust fans operate safely and efficiently for years to come.

Why Choose S.S. Insulation and Equipments India Pvt. Ltd. for Hammer Exhaust Fan in India?

- • Deep Domain Expertise: Over four decades specializing in industrial ventilation have honed our engineering precision and project execution.

- • Certified Quality & Compliance: Every fan is BIS ISI-marked, CEA-approved, and optionally PESO/ATEX-certified, ensuring safety and regulatory adherence.

- • Turnkey Bulk Solutions: From initial survey through export logistics, installation, and maintenance, we manage every step—so you meet tight timelines without hassle.

- • Proven Performance & Support: Trusted by 500+ clients, our fans reduce energy costs, improve indoor air quality, and come with 24/7 technical assistance and preventive-maintenance plans.

Get Hammer Exhaust Fan in India from S.S. Insulation and Equipments India Pvt. Ltd.

Ready to optimize your facility’s airflow?

- • Request a Quote: Call +91-7972791358 or email sales@ssinsulationindia.com

- • Download Spec Sheet: Access complete product details instantly

- • Visit Us: Plot No. 10A, Chakan, Pune – 410501, Maharashtra, India

Ensure maximum ROI, unwavering compliance, and unmatched durability with our industry-leading hammer exhaust fans.