How to choose the best industrial explosion valve

manufacturers?

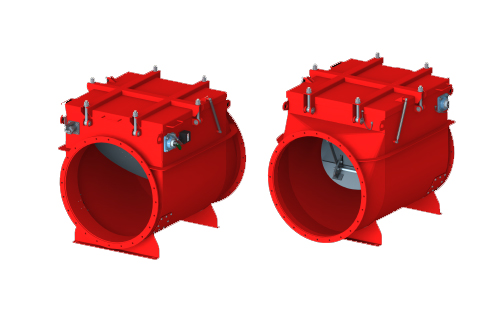

Industrial explosion isolation valve manufacturers in nashik

often provide their customers with various customization solutions to meet their

specific industrial needs. They provide a variety of valve sizes, materials and

configurations to meet specific applications. In this regard, one can even

include chemical processing and food production or pharmaceutical manufacturing.

With collaboration with an innovative manufacturer, you can get the best deals

available in town.

1. Research the Manufacturer's Reputation

Online Reviews and Ratings: Look for customer reviews on trusted

platforms like Google, industry forums, and third-party review sites. Good

testimonials and ratings show that it is reliable.

Next, you will have to look for their Industry Experiences

and choose manufacturers who have experience in the field. Check if the

company has industry-specific certifications such as ISO 9001, CE Marking,

or NFPA compliance, which would mean quality and safety standards.

2. Evaluate the Product Range

A reputable manufacturer offers various dust extraction

systems to meet the needs of different industries and customers. These

include baghouse systems, cyclone dust collectors, cartridge filters,

and portable extractors.

Consider customization options so that the system

meets your particular operational needs.

3. Technological Innovation

Energy Efficiency: The most popular Industrial

dust extraction system manufacturers in nashik often designs

with energy efficiency in mind to cut down on operating

expenses.

Advanced Features: Look for systems with

smart technology, such as automated cleaning mechanisms,

real-time monitoring, and IoT compatibility for seamless

integration.

Noise Levels: Choose systems that can be

installed in a quiet manner if noise reduction is

important.

4. Check References and Case

Studies

Ask for case studies or references

to know how the Best dust extraction system

manufacturers in nashik have overcame similar

challenges in the same industry or project.

Get to talk to previous

customers to get an idea of what the

manufacturer product is and the after-sales

service.

5. Check After-Sales

Support

Major manufacturers provide

proper after-sales support based on

maintenance services, availability of spare

parts, and technical support.

Warranty terms and

customer care responsiveness should be

checked to gain confidence

post-purchase.

6. Compliance

with Laws

The manufacturer

should conform to the safety and

environmental regulations in the

local and international regions. For

example, in specific regard, it must

adhere to OSHA, NFPA, and EPA

requirements, thereby ensuring safe

use and environmentally friendly

system.

7. Cost and

Value Comparison

Though cost is

important, value is better than

the price. Instead of

considering its actual cost of

installing the system, consider

its total cost of ownership that

includes installation,

servicing, and energy

consumption.

Get

quotations from various

manufacturers and compare

their products.

8.

Industry Networking

Visit

trade shows,

exhibitions, and other

conferences that many

manufacturing companies

attend. Many top

manufacturers will

display their current

lines. Networking with

other peers and industry

experts can lead to safe

manufacturers.

9. Scalability

It

would be best if the

systems were

scalable to your

business. For

industries to expect

growth and

expansion, this is

especially

important.

10. Eco-Friendly

Brands

Partner with

eco-friendly

brands. Energy

efficiency is

emphasized in

their design,

with

power-efficient

systems and a

'green' solution

for many

producers.

Corporate

responsibility

is manifest

through

cooperation with

such companies.